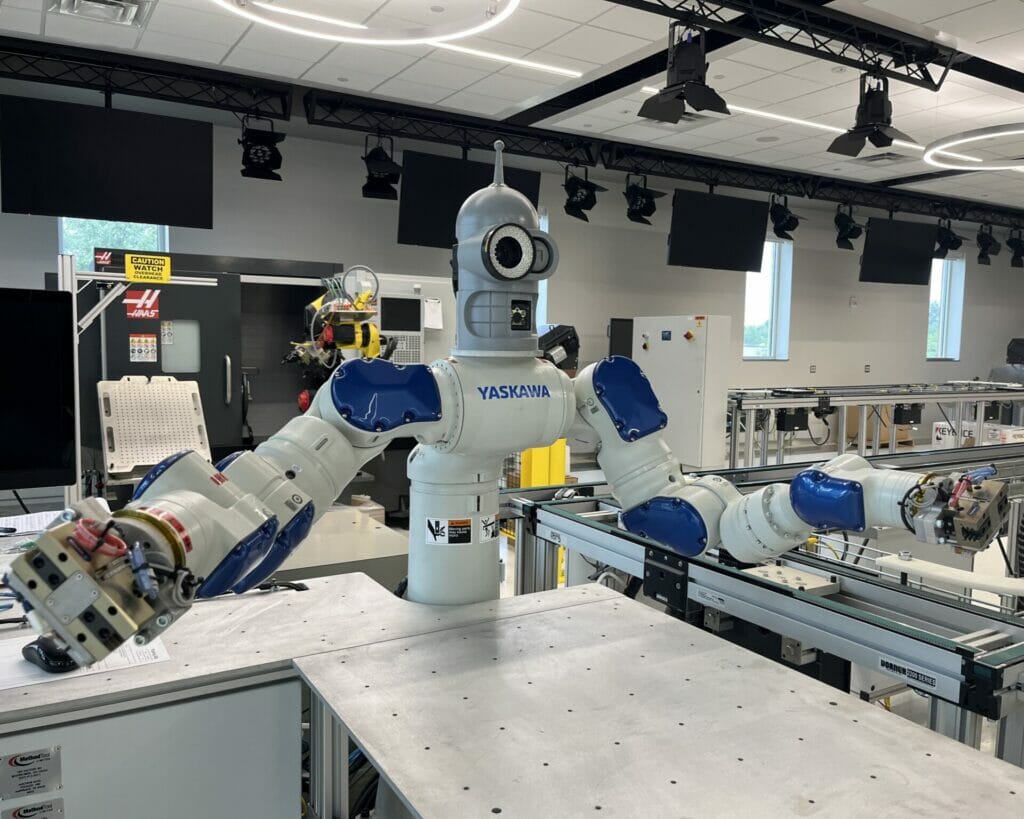

The Industry 4.0 Integration Lab inside the Center for Manufacturing Advancement (CMA) is an autonomous manufacturing work cell featuring several robots and machines communicating via network signals. This demonstration site is a self-contained digital ecosystem that showcases an end-to-end manufacturing environment and can be customized for specific scenarios.

The lab is ideal for manufacturers interested in optimizing processes, exploring automation in their own processes and becoming globally competitive.

Filled with equipment from a variety of different technology providers, the space provides integration opportunities to demonstrate and teach Industry 4.0 concepts, such as industrial Internet of Things process monitoring.

The Industry 4.0 Integration Lab is housed inside the Center for Manufacturing Advancement (CMA) on the campus of the Institute for Advanced Learning and Research (IALR).