The June 2024 edition of IALR at a Glance is jam-packed with exciting news and updates! Learn more about…

- Jason Wells Join IALR as EVP, Manufacturing Advancement

- Linda Green Wins Chamber Award

- STEM Camps are filling up fast

- Much more!

The June 2024 edition of IALR at a Glance is jam-packed with exciting news and updates! Learn more about…

Alan Pearce, the CEO of Danville-based metal additive manufacturing company FasTech, wanted fresh perspectives on improving the company’s standing as a great place to work.

Who did he turn to for those insights?

A bunch of high school juniors from the Academy for Engineering and Technology (AET).

Through the Next generation Of Work (NOW) teamship program, three teams of high school juniors collaborated with coaches and Pearce to get to the root of the issue and identify possible solutions. As part of the 2024 cohort of the NOW teamship program, 17 students worked with two organizations—FasTech and the Virginia Talent + Opportunity Partnership (V-TOP).

Pearce was amazed by the professionalism, data and knowledge these students shared. His company is trying to recruit two of them to work as interns over the summer, allowing them to execute some of their ideas.

Alan Pearce, CEO of FasTech LLC, listens to a presentation from high school juniors from the Academy for Engineering and Technology as part of the Next generation Of Work (NOW) teamship program.

“When they made their presentation, my biggest regret was that I didn’t bring my management team with me. It was a great professional presentation with some strong data.” – Alan Pearce, CEO, FasTech LLC

This is the fourth year AET students have participated in the teamship model, which is spreading across other Southern Virginia localities. IALR also supported a teamship program for college students in the Hampton Roads region.

“This is an excellent thing to connect schools and business, for both sides,” Pearce said. “The businesses get to start younger, and maybe we can help steer these students.”

The teamship model is straightforward: a business presents an open-ended problem to a group of students who, with guidance from a coach, work together to provide solutions.

Past problems have focused on issues such as new product adoption, staffing difficulties and environmental regulations.

“The NOW teamship program provides our AET students with a memorable, impactful work-based learning experience. They learn critical thinking and collaboration skills while providing valuable insights to a business.” – Dana Silicki, IALR, Advanced Learning Program Manager

The primary objective of the teamship experience is to provide the student participants with two essential skills: effective collaboration and problem-solving. Through interview sessions with the businesses, research and data analysis, students figure out the problem and its full context—a critical step in offering potential solutions.

District C, a North Carolina-based nonprofit, developed this framework and is spreading the model throughout the United States.

The model, which was designed to provide value to businesses and benefit the student participants, is part of IALR’s work-based learning system that connects students to careers. With just a five-hour time commitment, companies can gain fresh perspectives on complex problems at no cost, all while helping develop future talent. Students learn to utilize four critical career mindsets—analytical, design, collective and self-aware—not just to solve the problem but to understand it in full.

Gavin Shields (middle), a junior in the AET program who participated in the teamship program, learned the importance of collaborating with people who have different ideas.

The framework can be customized. For instance, the AET students typically complete the experience in about a month while other organizations may facilitate a more intensive process in just a week.

The other organization that offered a problem for AET students to solve was the Virginia Talent + Opportunity Partnership, which aims to improve the internship readiness of Virginia students, institutions and employers. (IALR leads the V-TOP innovative internship effort in GO Virginia Region 3, serving 15 localities across Southern Virginia.)

The main question these students tackled was: How can V-TOP increase student engagement and awareness? V-TOP needs secondary and postsecondary students to place in internships.

Two student teams took two approaches. One focused on improving digital marketing, while the other looked at grassroots efforts. Their recommendations were simple and actionable.

“I was very impressed with the level of detail they went into, trying to make sure they knew exactly what the problem was and understanding what we are already doing. I thought their insights were very, very valuable.” – Kiana Dillard, IALR Work-Based Learning Coordinator, V-TOP Region 3 Program Coordinator

Kiana Dillard (right), Work-Based Learning Coordinator and V-TOP Region 3 Program Coordinator, discusses the next steps offered by a group of high school juniors through the NOW teamship program.

Gavin Shields, a junior in the AET program who focused on the digital marketing side, learned the importance of collaborating with people who have different ideas.

“We got to solve a real-world business problem, and it felt cool because we were doing something that meant something in school. And we found the root of the problem like we were supposed to. We contributed a lot of new knowledge and ideas.” – Gavin Shields, AET Junior

Dillard will soon join three other IALR staffers – Advanced Learning Program Managers Jessie Vernon and Dana Silicki and John Hatchett, AET Coordinator who is employed by Danville Community College – as a certified coach with District C.,

“I’m seeing this model from all ends,” Dillard said. “It’s just great, and I look forward to coaching students through this process in the future.”

IALR and AET were the first Virginia-adopters and piloted the District C teamship program with students from AET, which has led to the model spreading across Southern Virginia. Chatham High School Teacher Tara Stafford has run cohorts in the past two years, focusing on problems from the Danville Otterbots and The Bee and Holbrook Hotels.

Teachers from Halifax and Brunswick have been certified, with Lunenburg planning to implement teamship soon.

On the eastern side of the state, Michelle Simmons, V-TOP Project Manager for Region 5 covering the Hampton Roads area, worked directly with District C to get certified as a teamship coach. Simmons and the Teamship Committee decided to implement a week-long intensive experience for college students with both a virtual and in-person option.

“VTOP regional leadership wanted to provide a unique, internship opportunity to students in the region. We hope that sharing our experience with implementing this program will encourage school districts, institutions, and employers to adopt Teamship in their respective spaces.” – Michelle Simmons, V-TOP Region 5 Project Manager

Simmons wanted someone experienced in facilitating teamship programs to provide support, which led her to IALR Advanced Learning Program Manager Jessie Vernon, who led the virtual option for seven students.

“I was so excited when Michelle said they were implementing the teamship model this summer! One of the beautiful things about teamship is its versatility. We utilize the model as a part of the AET junior seminar class over a one-month period. The Hampton Roads program was a one-week intensive, completely outside a class. We haven’t run a virtual teamship program since 2020; the Hampton Roads program had both an in-person and virtual option. As secondary and postsecondary schools try to connect more students with high quality work-based learning experiences, teamship is a great option.” – Jessie Vernon, Advanced Learning Program Manager, IALR

A rising junior at Norfolk State University with a major in Business Marketing and a minor in Mass Communications, McKensi Rice was one of the virtual participants in the teamship opportunity.

“When I saw that we would be working with a real company, this is the experience I need for my future career. And it fit well with my schedule.” – McKensi Rice, Norfolk State University

Rice and the other students worked with the 757 Collab, an innovation network serving the greater Hampton Roads area, on discovering key metrics to measure success and ways to incentivize innovation and improve the company’s culture.

“This experience was eye-opening and very positive,” Rice said. “It was only five days, but I learned a lot about myself and how to work with others.”

IALR is looking for businesses as well as educators that would be interested in participating in the NOW teamship program. Those who are interested should contact Jessie Vernon, Advanced Learning Program Manager at IALR.

A specialized camera that shoots up to 400,000 frames per second, allowing true slow-motion views of the manufacturing process.

Cutting-edge sensors that measure factors like cutting force and harmonic vibrations.

Infrared cameras that show temperature patterns throughout an operation.

These are just a few of the specialized pieces of equipment within the Computer Numerical Control (CNC) Machining Innovation Lab, which is housed inside the Institute for Advanced Learning and Research’s (IALR) Center for Manufacturing Advancement (CMA). The CNC Machining Innovation Lab also plays a crucial role in the U.S. Navy’s Additive Manufacturing Center of Excellence (AM CoE), also housed within the CMA.

Featuring state-of-the-art equipment and cutting-edge technology, the CNC Machining Innovation Lab will support private industry through testing services and process optimization and help the AM CoE develop world-leading additive manufacturing “recipes” for the development of parts needed by the U.S. military.

“The vision of the CNC Machining Innovation Lab is twofold. We support the AM CoE, but we also have a vision to support industry. We’re trying to develop partnerships to help industry drive innovation and productivity with increased profitability in a rapidly changing environment.” — Kevin Thompson, Operations Manager for the Center for Manufacturing Advancement, IALR

Computer Numerical Control (CNC) Machining is a manufacturing process where computer-controlled machines create precise and intricate parts and components. Commonplace in industries such as aerospace, electronics and healthcare, this is a subtractive manufacturing process – meaning that an existing block or item is whittled down or shaped.

The CNC Machining Innovation Lab partners with public and private manufacturers of all sizes to modernize their processes, identify and integrate emerging technologies and provide data-driven process development and optimization. Some of the capabilities include process development, process optimization, CNC programming, the integration of emerging technology, automation integration, turn-key solutions and application engineering support.

“Companies don’t have the capacity to be able to stop and try a new process. They have to find external ways of doing that, and that’s a huge role we can play. Companies can present a challenge to us and continue to produce goods while we develop a solution that suits their needs.” — Jeremiah Williams, CNC Technologist, IALR

The CNC Machining Innovation Lab boasts a broad inventory of specialized equipment, including sensors to measure factors like cutting force, slow-motion cameras to track chip formation, infrared cameras to analyze the impact of heat and much more, all with the goal of “trying to optimize processes for customers,” Thompson explains. IALR is even allowing other companies to test and utilize specialized sensors inside of the CNC Lab machines for data collection.

“Our job is not to compete with industry. Our job is to support industry.” – Kevin Thompson, Operations Manager for the Center for Manufacturing Advancement, IALR

Businesses can:

The CNC Machining Innovation Lab is ISO 9001:2015 compliant, reassuring customers and partners alike that we have an internationally validated system in place to address and prevent quality issues.

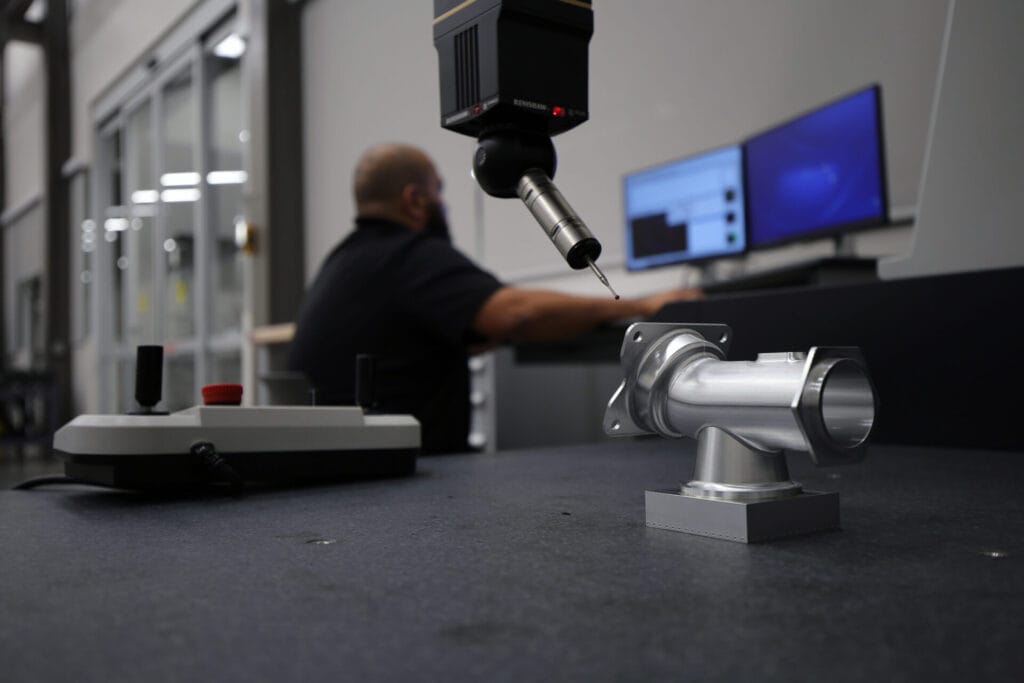

The CNC Machining Innovation Lab is located across from the CMA’s state-of-the-art Metrology Lab that features one of the largest Coordinate Measuring Machines (CMM) on the East Coast with 3D scanning capability along with optical measurement systems, hardness and roundness testers and support equipment. Through a partnership with Mitutoyo and Master Gage & Tool, IALR offers the services of the Metrology Lab to regional businesses and partners who may not otherwise have access to such capabilities.

“The Metrology Lab is ideal for emerging or developing businesses to have access to this capability while building justification for their own capital investment.” – Kevin Thompson, Operations Manager for the Center for Manufacturing Advancement, IALR

“Everything we do at IALR involves partnerships and is driven by the needs of industry. Through the CNC Machining Innovation Lab and the Metrology Lab, IALR is simultaneously contributing to our nation’s defense and supporting current, new and prospective companies in Southern Virginia with needed services.” – Telly Tucker, IALR President

The CMA also includes a dynamic Industry 4.0 Integration Lab that serves as a demonstration site, showing manufacturing companies what is possible. Companies that are interested in partnering with IALR in the CNC Machining Innovation Lab or in the CMA should contact the IALR team.

The submarine industrial base (SIB) is a system of thousands of companies that produce parts and equipment used in the production and maintenance of submarines for the U.S. Navy. IALR has partnered with the U.S. Navy – along with many other public and private organizations – in a two-pronged approach to support the SIB, the development of new submarines, and the maintenance of the existing fleet: the federal Accelerated Training in Defense Manufacturing (ATDM) program and the U.S. Navy’s Additive Manufacturing Center of Excellence (AM CoE).

ATDM increases the pool of skilled labor in areas like additive manufacturing, CNC machining, welding, metrology and non-destructive testing – trades that are needed by the SIB. On the other hand, the AM CoE is focused on implementing additive technologies and processes that will allow for more efficient development of parts. Don Hairston, General Manager of Austal USA Advanced Technologies, used the analogy of making cookies during a recent presentation at the ATDM AM CoE Summit at IALR. When making cookies and especially in manufacturing parts for the U.S. Navy, each of these variables must be accounted for and done correctly for successful production: raw materials, equipment, manufacturing know-how, post-processing and finishing and quality control.

In the simplest terms, “scaling the supply chain” is one of the primary goals of the AM CoE, Hairston explained.

The AM CoE will scale and mature additive technologies that enable innovative production of submarine components to bolster naval shipbuilding and repair supply chains. Involving nine different partners, the AM CoE will increase overall manufacturing capacity and close the supply-demand gap in critical markets like castings, forgings, fittings and fasteners.

The AM CoE team will develop new technical data packages (TDP), which are essentially comprehensive “recipes” for how to utilize additive manufacturing techniques to manufacture particular components. The workflow inside the AM CoE will typically go something like this:

As part of the Navy’s AM CoE, the CNC Machining Innovation Lab will be utilized after the initial printing of a part, verifying that the design used for additive manufacturing can successfully be machined. Simultaneously, the IALR team will also explore and implement advanced strategies that better align with today’s manufacturing equipment and methods.

“Basically, what we will do is verify that the part that has been printed can be successfully and correctly machined without any issues.” – Jeremiah Williams, CNC Technologist

Additive manufacturing, which can also be referred to as 3D printing, is a subset of manufacturing where an object is built “from the ground up” based on a 3D model. It may seem odd that a subtractive manufacturing method would play such an integral role in the Navy’s additive manufacturing operations. While 3D printing and additive manufacturing are the primary focus of the AM CoE, subtractive methods are still essential in creating and verifying any part.

“With the current technology and dimensional requirements of the parts, you can’t simply print and install a component. You’re going to have to print it and then do some final subtractive work before the part can be utilized.” – Jeremiah Williams, CNC Technologist

Once perfected and tested, the TDPs will be shared with Navy suppliers, providing them with the “recipe” they need to produce the part correctly and efficiently. As of mid-October, the AM CoE has released 28 TDPs to the companies that will be manufacturing the parts.