Inside the Institute for Advanced Learning and Research (IALR) Industry 4.0 Integration Lab, students from the Accelerated Training in Defense Manufacturing (ATDM) program and their instructor examine the robots, fixtures, work areas and CNC machines. They take detailed measurements and ask questions.

Butch Kendrick, IALR’s Director of Digital Manufacturing, has explained several “problems” he’s encountered in the lab. He asks these students to develop creative solutions using additive manufacturing to design and print different fixtures; the goal is to better support the Industry 4.0 Integration Lab’s mission of demonstrating and teaching Industry 4.0 concepts.

During the four-month program that prepares adult learners to work in the Maritime Industrial Base (MIB), ATDM students don’t just learn theory; they tackle real-world problems.

“Working on real projects while in the ATDM program significantly enhances the students’ readiness and confidence as they enter the workforce.” – Cheryl Terry, Director of ATDM Training and Technology, IALR

ATDM: Rapid Training for Meaningful Careers

The Accelerated Training in Defense Manufacturing program at IALR is a hands-on training initiative designed to address the MIB workforce needs.

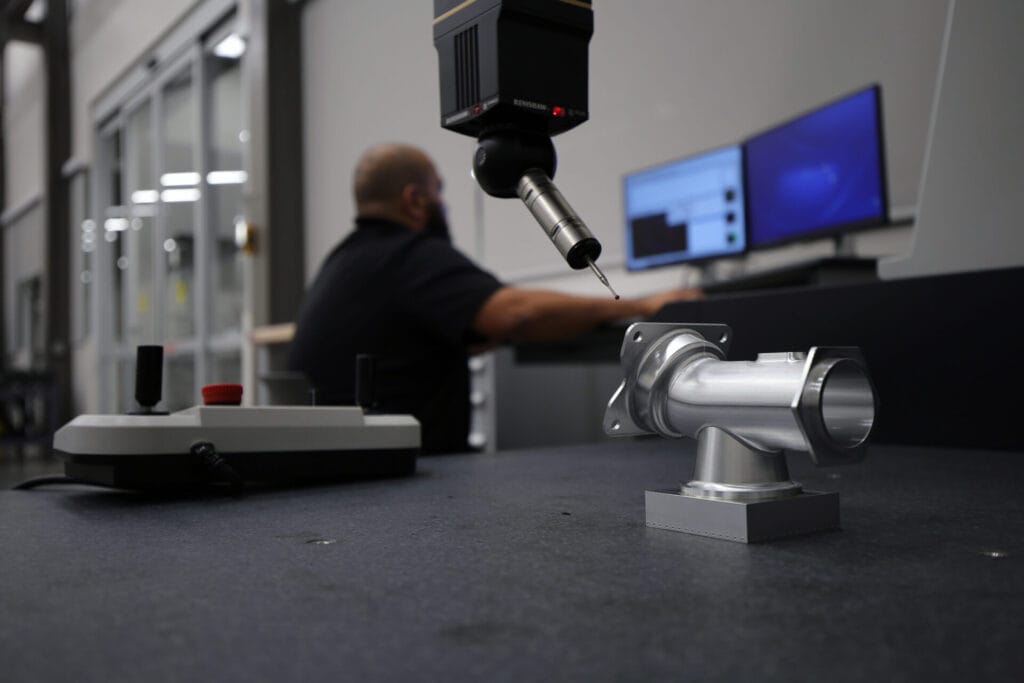

Currently, ATDM offers tracks in welding, additive manufacturing, CNC machining, quality control inspection (metrology) and non-destructive testing (NDT). Students benefit from tuition-free training, supportive services and guaranteed opportunities to earn industry-recognized certifications.

ATDM’s emphasis on real-world, hands-on learning ensures that students gain practical skills directly applicable to manufacturing challenges.

“We get so much more buy-in from our students when they work on real-world situations. They get more gratification from fixing problems than just doing their homework.” – Tim Holland, ATDM Additive Manufacturing Instructor, IALR

Student-Driven Fixture Design Project

To date, every cohort of additive manufacturing students has worked on a project in the Industry 4.0 Integration Lab. One of the first cohorts actually 3D printed the head of Rosie, one of the lab robots. The robot was designed to look like Bender from Futurama and eventually got the name Rosie from a Facebook naming poll.

Aaron Jacob Garcia with Rosie

“I make sure that the students understand the purpose of what they’re doing and how it all connects,” Kendrick said. “Once we do the initial session with them, the lab is open to them coming back and taking measurements and doing whatever they need to do.”

This cohort tackled four projects, including refining an existing fixture to ensure better robotic interaction and stability. Students fully managed their designs, from taking precise measurements to ensuring the fixture would securely interface with multiple table configurations.

“There is a problem, and they have to figure out how to fix it, but there’s no instruction list on how to do it,” Holland said.

Recent graduate Aaron Jacob Garcia said the experience taught him about the potential of additive manufacturing, the need for detailed, reliable measurements and the importance of understanding the end use.

“I learned that sometimes you have to make changes to make a part work for what it will be used for,” he said.

The Natural Partnership with Industry 4.0 Integration Lab

Allowing additive manufacturing students the opportunity to contribute to the Industry 4.0 Integration Lab is mutually beneficial.

“I think it’s a great opportunity for students to come out of the classroom into a real-life situation that isn’t too high pressure,” said Kendrick. “It gives them a chance to take what they’ve learned, mix it with their imagination and see what they can come up with.”

The Industry 4.0 Integration Lab provides an autonomous manufacturing environment featuring advanced robotics, automation and digital technologies. This focus makes it an ideal platform for training future manufacturing professionals, demonstrating real-world Industry 4.0 principles, and creating tangible outcomes for students and industry partners.

The Lab is housed within the Center for Manufacturing Advancement (CMA) on the IALR campus. The CMA equips manufacturers to be globally competitive by supporting the seamless integration of emerging technology into manufacturing processes.

“Allowing students to participate in these types of real-world, hands-on projects is mutually beneficial for everybody involved and furthers the mission of both the ATDM program and the CMA.” – Jason Wells, Executive Vice President, Manufacturing Advancement, IALR