300,000

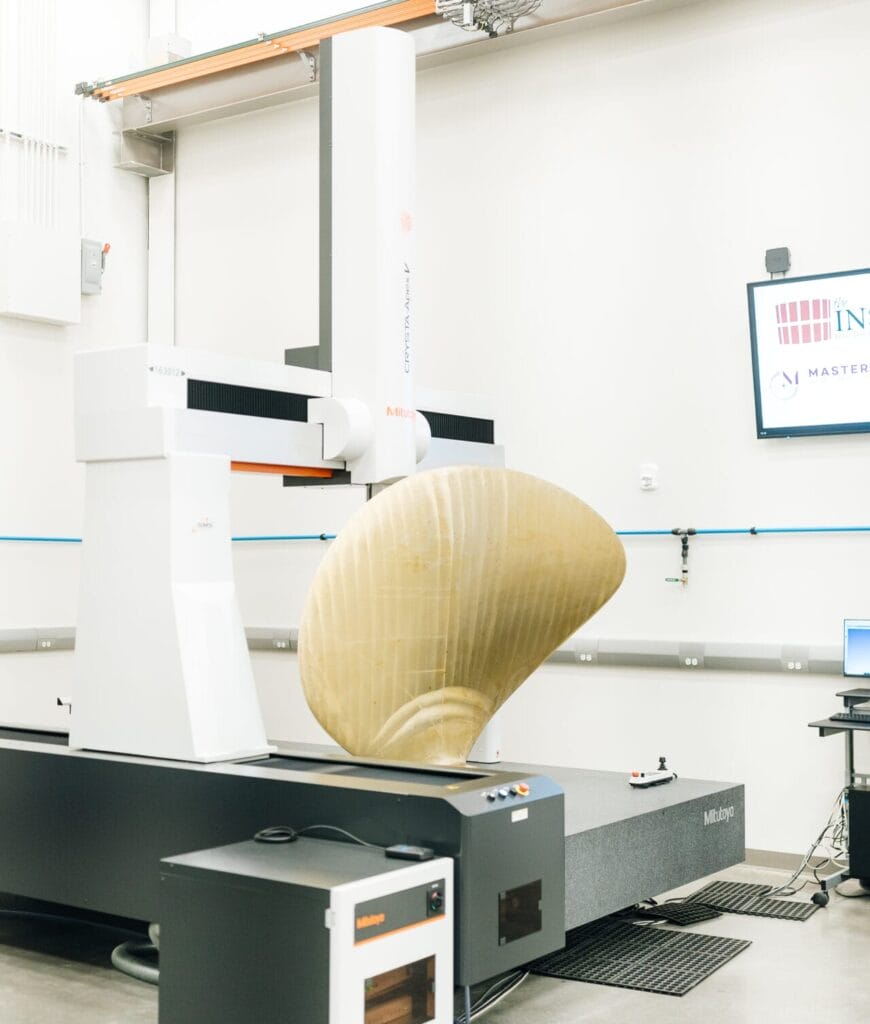

That’s how many points are scanned per second on the laser scanner on the Mitutoyo Crysta-Apex V163012 Coordinate Measuring Machine (CMM), one of the largest on the East Coast. Even a relatively small part has tens of millions of scannable points. In addition to the laser scanner, the CMM boasts a variety of unique qualification and measurement capabilities.

Equipped with the CMM and a bevy of other top-tier qualification tools and equipment, the Institute for Advanced Learning and Research’s (IALR) Metrology Lab provides critical measurement and qualifications services for the Navy’s Additive Manufacturing Center of Excellence (AM CoE) and has the capability to provide support for private industry. Located inside the Center for Manufacturing Advancement in Southern Virginia, the Metrology Lab with NIST Certified Inspection is the result of strong partnerships. IALR owns the equipment and space, but applications engineers with Mitutoyo and Master Gage & Tool Co. operate the equipment.

“The Metrology Lab is a unique resource for local industry and a key component of the Navy’s efforts to improve additive technologies and processes. The Metrology Lab also epitomizes several core tenets of IALR, including our mission of economic transformation, commitment to partnerships and penchant for utilizing state-of-the-art technology.” – Tim Robertson, Chief Operating Officer, Manufacturing Advancement

Top-Tier Metrology Through Partnerships

Top-Tier Metrology Through Partnerships

Metrology, officially defined as the science of measurement, is a crucial element of any manufacturing process. In the Metrology Lab at IALR, application engineers can perform relatively simple measurements, such as physical dimensions, and highly complex qualifications of factors like shape, hardness and many other physical qualities.

The CMM inside the Metrology Lab can perform some of the most sophisticated yet critical measurement and qualification processes possible. It has a work area that can accommodate pieces as large as five feet wide, nearly 10 feet long and almost four feet tall, but the space can also be used for smaller parts. For instance, staff could place dozens of the same parts on the surface area and program the CMM to perform identical qualification tasks on each.

“The Mitutoyo Crysta-Apex V163012 Coordinate Measuring Machine can pretty much do any type of inspections that would be needed in the industry.” – Carlos Cabello, Applications Engineer, Mitutoyo

Every measurement the machine makes is down to the micron.

Some of the services offered by the Metrology Lab with NIST Certified Inspection include:

- Contract inspection

- CMM programming

- Laser scanning

- Automation integration

- Reverse engineering

- Calibration services

- Application engineering support

Qualification and Measurement for Navy and Industry

The Navy established its Additive Manufacturing Center of Excellence (AM CoE) inside the CMA. Tasked with scaling and maturing additive technologies for the production of submarine components to bolster naval shipbuilding and repair supply chains, the AM CoE includes the Navy and nine other organizations. The AM CoE team develops new technical data packages (TDP), which are essentially comprehensive “recipes” for utilizing additive manufacturing, or 3D printing, techniques to manufacture particular components.

The Metrology Lab – as well as the CNC Machining Innovation Lab that IALR owns and operates – plays a critical role in this operation. In fact, the team in the Metrology Lab will conduct three separate inspections of every part:

- Initial inspection after a part is 3D printed. The team will compare physical measurements to the Computer-Aided Design (CAD) model.

- After heat treatment, the team conducts another inspection to ensure that the part holds its shape.

- After final CNC machining work is completed, the team conducts a final inspection that involves checking every dimension.

“It’s very honorable work, and I’m very proud to be a part of this project.” – Sean Cobb, Master Gage and Tool

While the AM CoE utilizes the lab to complete numerous inspections, the partners can also use the equipment to provide services and support to industry. The CMM and other equipment allows industry in need of testing support to accurately and affordably measure and certify products.

“In order for a company to do this level of measurement and qualification, they’re going to have to make major capital investments and slow down production. We can provide those testing services in a convenient and certified way without impeding production.” – Kevin Thompson, CMA Operations Manager

The Center for Manufacturing Advancement, which houses the Navy’s AM CoE and impactful technology and resources like the Metrology Lab, is located in Danville, Virginia, on the IALR campus. Companies that are interested in partnering with IALR in the CMA by utilizing the services of the Metrology Lab, collaborating with the CNC Innovation Lab, or learning about automation in the Industry 4.0 Integration Lab should contact the IALR team.