The April 2025 edition of IALR at a Glance is packed with exciting news and updates! Learn more about…

- Largest ATDM Cohort graduates

- Family Literacy Night recap

- Summer STEM educator opportunity

- Much more!

The April 2025 edition of IALR at a Glance is packed with exciting news and updates! Learn more about…

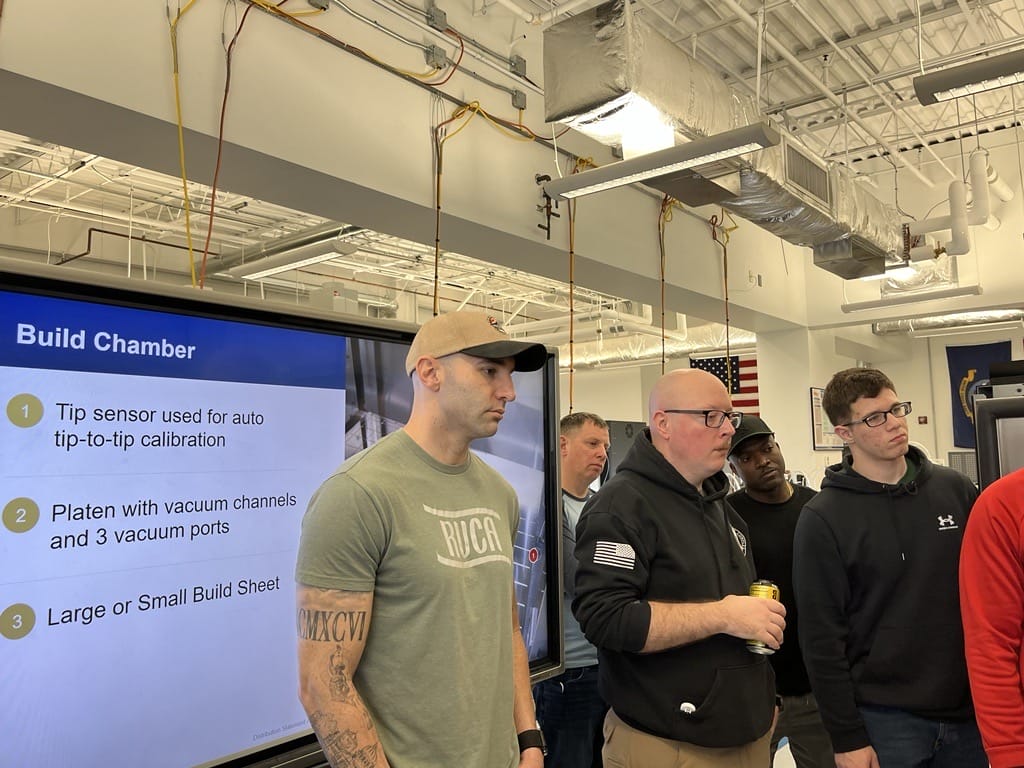

Inside the Institute for Advanced Learning and Research (IALR) Industry 4.0 Integration Lab, students from the Accelerated Training in Defense Manufacturing (ATDM) program and their instructor examine the robots, fixtures, work areas and CNC machines. They take detailed measurements and ask questions.

Butch Kendrick, IALR’s Director of Digital Manufacturing, has explained several “problems” he’s encountered in the lab. He asks these students to develop creative solutions using additive manufacturing to design and print different fixtures; the goal is to better support the Industry 4.0 Integration Lab’s mission of demonstrating and teaching Industry 4.0 concepts.

During the four-month program that prepares adult learners to work in the Maritime Industrial Base (MIB), ATDM students don’t just learn theory; they tackle real-world problems.

“Working on real projects while in the ATDM program significantly enhances the students’ readiness and confidence as they enter the workforce.” – Cheryl Terry, Director of ATDM Training and Technology, IALR

The Accelerated Training in Defense Manufacturing program at IALR is a hands-on training initiative designed to address the MIB workforce needs.

Currently, ATDM offers tracks in welding, additive manufacturing, CNC machining, quality control inspection (metrology) and non-destructive testing (NDT). Students benefit from tuition-free training, supportive services and guaranteed opportunities to earn industry-recognized certifications.

ATDM’s emphasis on real-world, hands-on learning ensures that students gain practical skills directly applicable to manufacturing challenges.

“We get so much more buy-in from our students when they work on real-world situations. They get more gratification from fixing problems than just doing their homework.” – Tim Holland, ATDM Additive Manufacturing Instructor, IALR

To date, every cohort of additive manufacturing students has worked on a project in the Industry 4.0 Integration Lab. One of the first cohorts actually 3D printed the head of Rosie, one of the lab robots. The robot was designed to look like Bender from Futurama and eventually got the name Rosie from a Facebook naming poll.

Aaron Jacob Garcia with Rosie

“I make sure that the students understand the purpose of what they’re doing and how it all connects,” Kendrick said. “Once we do the initial session with them, the lab is open to them coming back and taking measurements and doing whatever they need to do.”

This cohort tackled four projects, including refining an existing fixture to ensure better robotic interaction and stability. Students fully managed their designs, from taking precise measurements to ensuring the fixture would securely interface with multiple table configurations.

“There is a problem, and they have to figure out how to fix it, but there’s no instruction list on how to do it,” Holland said.

Recent graduate Aaron Jacob Garcia said the experience taught him about the potential of additive manufacturing, the need for detailed, reliable measurements and the importance of understanding the end use.

“I learned that sometimes you have to make changes to make a part work for what it will be used for,” he said.

Allowing additive manufacturing students the opportunity to contribute to the Industry 4.0 Integration Lab is mutually beneficial.

“I think it’s a great opportunity for students to come out of the classroom into a real-life situation that isn’t too high pressure,” said Kendrick. “It gives them a chance to take what they’ve learned, mix it with their imagination and see what they can come up with.”

The Industry 4.0 Integration Lab provides an autonomous manufacturing environment featuring advanced robotics, automation and digital technologies. This focus makes it an ideal platform for training future manufacturing professionals, demonstrating real-world Industry 4.0 principles, and creating tangible outcomes for students and industry partners.

The Lab is housed within the Center for Manufacturing Advancement (CMA) on the IALR campus. The CMA equips manufacturers to be globally competitive by supporting the seamless integration of emerging technology into manufacturing processes.

“Allowing students to participate in these types of real-world, hands-on projects is mutually beneficial for everybody involved and furthers the mission of both the ATDM program and the CMA.” – Jason Wells, Executive Vice President, Manufacturing Advancement, IALR

The Accelerated Training in Defense Manufacturing (ATDM) program celebrated its 15th and largest graduating cohort with a ceremony held at the Institute for Advanced Learning and Research (IALR) on March 14. The event honored 98 graduates who completed four months of intensive manufacturing training on the IALR campus in Additive Manufacturing, CNC Machining, Non-destructive Testing and Welding.

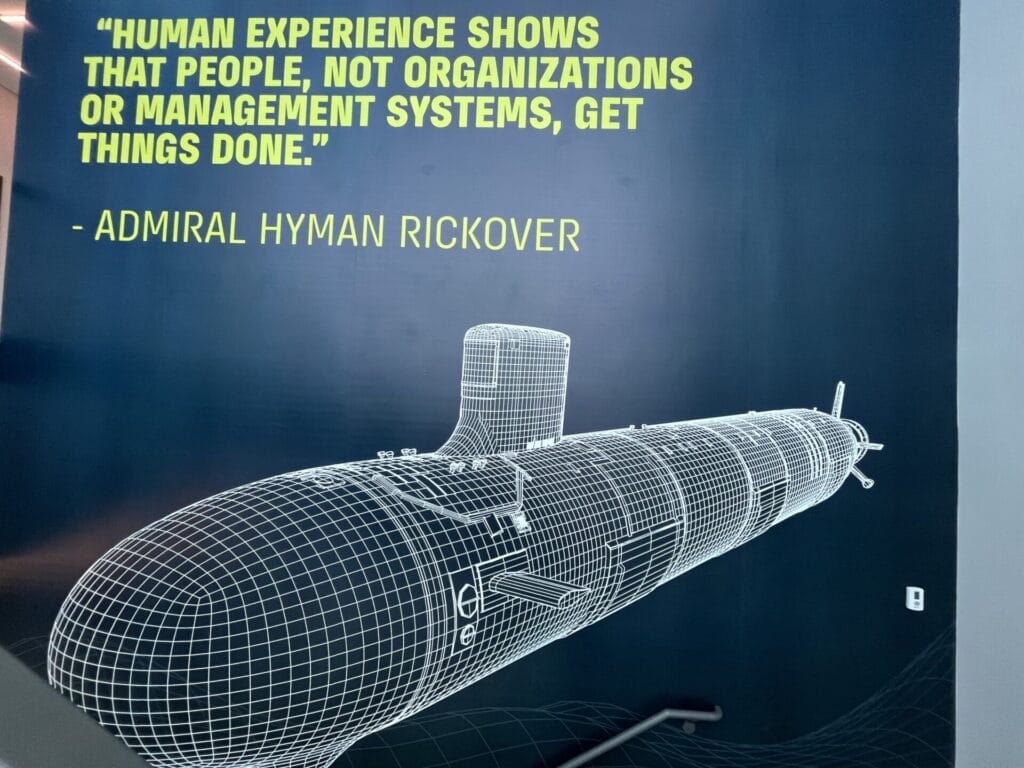

The ceremony featured a keynote address by Captain James P. “JIP” Mosman, Commander of the Norfolk Naval Shipyard, and student remarks by Jonathan Rada, who completed the Additive Manufacturing program.

“The Maritime Industrial Base is the foundation of both our national security and global supply chain… Whether you are ensuring the structural integrity of a vessel, contributing to cutting edge innovation or supporting mission critical operations, you are playing a role in something much larger than yourself. You are joining a workforce in a legacy of service, resilience and innovation.” – Captain James P. “JIP” Mosman, Commander of the Norfolk Naval Shipyard

“I’ve learned invaluable skills, made lifelong friends and found a sense of a sense of purpose that has eluded me for years. It’s never too late to reinvent yourself, take risks, and when opportunity knocks, show up.” – Jonathan Rada, Additive Manufacturing Graduate, incoming CNC Machinist with General Dynamics

The ATDM program equips adult learners with critical skills and credentials to succeed in careers within the maritime industrial base (MIB), which produces and maintains essential parts and equipment for ships and submarines. ATDM participants receive full scholarships covering tuition and housing.

The curriculum is guided by direct input from industry partners, ensuring graduates meet the immediate workforce needs of defense manufacturers. Throughout their training, students complete 600 hours of hands-on instruction and earn multiple industry-recognized credentials. Many participants secure employment offers even before graduation.

Participants in the ATDM program come from across the United States, representing diverse backgrounds including veterans transitioning from military service, professionals changing industries and individuals new to manufacturing. With the Navy’s National Training Center that opened earlier in 2025, the program is set to train between 800 and 1,000 students annually.

Additive Manufacturing: Vincent Corbo, Joshua Davis, Talbert Dunn, Aaron Garcia, David Goree, Jim-Nicholas James, Michael McFadden, Lisa Parrotta, Alexander Peabody, Jonathan Rada, Sean Verrando

CNC Machining (1st Shift): Natasha Barnes, David Heil, Kevin Holodak, William Perry, Caleb Polasik, Rodrigo Van Rooy, James Wilson, Kamry Wilson

CNC Machining (2nd Shift): Nahid Bakhtari, Isaiah Booker, GianCarlo De La Paz, Majeed Ebrahimi, Chrday Fields, Julian Litlv, Daniel Pearce, Darcy Souza, Desmond Steele, Dustin Tatro, Xavier Thomas, Mace Tyrsdottir, Christopher Tucker

CNC Machining (3rd Shift): Carlos Bueno, William Cadwalader, Roberto Corona-Rodriguez, Claudio Gutierrez, Joshua Hjelle, Abuobaida Elamin, Padraic Noonan, Ryan Sanders, John Soltis, James Tyson

Non-destructive Testing: Edward Bakshis, Nathaniel Brown, Dustin Byrum, Zachery Carmean, DeAndre DeScott, Aquiles Guedes Rapassi, Nicole Hillstrom, Shawn Kizzee, Brandon Lay, Julian Littman-van Hoek, Trinidad Magdaleno, Kalief Manuel, Herbert McClain, Owen McNeill, Jessica Roy, Nicholas Sacharko, Zachary Snyder, Anna Stone, Mathew Walter, Aaron Watt

Welding (1st Shift): Ian Barba, Nicholas Barron, Jennifer Baumgartner, Thomas Cluchey, Michael Jenrich, Spencer Long, Anthony Mazzucca, Corey McWhorter, Anna Mikulec, Brandon Robinson

Welding (2nd Shift): Shonteniece Brown, Faith Chandler, Bethany Fairchild, Aiden Ferrell, Candace Green, Gracen Haught, J Nicholas Leppo, Peyton Phillips, Shaboo Reid, Santiago Rizo Lomeli, Ian Tamez, Rolando Velasco, Devin Walker

Welding (3rd Shift): Valdemarr Davis, Clayton Dierks, Emanuel Flores, Isaiah Forbes, Angel Gomez, Clay Hopper, Damien Jamison, James Kelly, Marquise Parker, Tyreek Robb, Britton Shover, Josue Sinico Velazquez, Carlos Walker

Accelerated Training in Defense Manufacturing was developed as a public-private consortium between the Department of Defense, IALR, Danville Community College (DCC), Phillips Corporation, and The SPECTRUM Group in consultation with the defense industry. IALR leads the multi-year pilot project funded by the National Imperative for Industrial Skills initiative of the Industrial Base Analysis and Sustainment Program Office in the Office of the Undersecretary of Defense for Acquisition and Sustainment.

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s major footprint focuses within Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg, along with the cities of Martinsville and Danville.

Effective learning blends theoretical instruction with real-world application. At the Institute for Advanced Learning and Research (IALR), hands-on training is a core principle across diverse programs.

“Theory is important, and it has value. However, my years working in and with educators has taught me that most learners are visual kinesthetic learners, and the most impactful learning tends to be hands-on learning.” – Telly Tucker, IALR President

This approach equips participants with practical skills and boosts their confidence in real job environments. Whether middle school students or seasoned adults, participants walk away with experiences they can immediately apply.

The Great Opportunities in Technology and Engineering Careers (GO TEC®) program exposes middle school students to the emerging technologies shaping tomorrow’s industries. Students learn about and, more importantly, get to practice with virtual reality welding tools, desktop CNC mills, different types of robots and much more, offering a direct glimpse into in-demand careers.

“Middle school is the perfect time to spark a lasting interest in STEM. Getting to touch and try these business-relevant technologies shows that advanced concepts and careers are within reach.” – Julie Brown, Ph.D., Vice President of Advanced Learning

Dual-enrollment students in the Academy for Engineering and Technology (AET)—a collaboration with Danville Community College and the local school divisions—learn concepts in the classroom and apply them immediately. This balance of theory and application strengthens their problem-solving abilities and prepares them for modern challenges.

“We’ve seen impressive results when students can test what they learn right away,” Dr. Brown says. “That combination pushes them to think critically and perform with confidence.”

IALR also houses students in the Piedmont Governor’s School for Mathematics, Science, and Technology. Every year, seniors in this program participate in a senior research project, some seeking support from IALR’s Applied Research division.

Accelerated Training in Defense Manufacturing (ATDM) equips adult learners with the skills needed to work with Navy suppliers in the Maritime Industrial Base. In just four months, participants build foundational knowledge and participate in hundreds of hours of hands-on practice with actual machinery.

“ATDM bridges the gap between classroom insights and real-world shop floors. Graduates leave ready to excel in high-demand defense manufacturing roles.” – Jason Wells, Executive Vice President of Manufacturing Advancement

In the Integrated Machining Technology (IMT) program, developed with Danville Community College, students face the pressure of meeting manufacturing quotas and deadlines. This setup mirrors the intensity of a true manufacturing environment.

“It’s a simulated manufacturing flow cell,” Wells said. “We put these students in a position to practice how all the pieces they’ve learned come together.”

IALR also hosts shorter programs on topics like Fanuc robotics, precision machining for instructors and industrial fermentation. These workshops blend conceptual lessons with live experimentation in a condensed timeframe.

“Our recent industrial fermentation workshop revealed how hands-on demos deepen understanding. When participants participate in the process, they gain a better understanding.” – Scott Lowman, Ph.D., Vice President of Applied Research, IALR

The journey does not end with a certificate or first job. Through various computer training workshops and the Wonder Community of Lifelong Learning, people can refresh their skills or discover new interests at any stage.

IALR’s commitment to lifelong learning and service learning opens pathways for professionals and hobbyists alike.

From virtual reality welding in GO TEC® to advanced precision machining in IMT, practical immersion helps learners of all ages gain a deeper understanding. Hands-on learning is particularly beneficial in the STEM fields, as shown by many different studies, including from Purdue University and the Proceedings of the National Academy of Sciences of the United States of America. With IALR’s goal of expanding STEM Capacity, this focus on hands-on, practical learning is what drives success.

“Practical experiences let learners see immediate results,” Tucker says. “When students engage directly, they become more prepared for today’s job market.”

Browse Educational Programs and Services

This episode features Daniel Hyler and Tim Holland—two graduates turned additive manufacturing instructors with the Accelerated Training in Defense Manufacturing (ATDM) program. Hear them discuss lessons they picked up along the way, plus real-world applications of additive manufacturing in today’s job market.

Listen in as they discuss:

In this episode, Senior Facilities Manager Stewart East and Assistant Director of Advanced Training and Operations Wesley Cifers explain:

Preparation: Months of logistical strategizing for a multi-phase relocation

Execution: Coordinating staff, resources, and external partners over the holidays

Outcome: A smoother transition to the Navy’s National Training Center, where the Accelerated Training and Defense Manufacturing (ATDM) program now has a permanent home

Episode highlights include:

DANVILLE, Va. — The U.S. Navy strengthened its efforts to revitalize the nation’s shipbuilding capability with the opening of a new training center in Danville, Virginia.

The Accelerated Training in Defense Manufacturing (ATDM) program, launched in 2021, has graduated more than 777 students from 45 states, Guam, Puerto Rico, and Australia. About 25% of participants are veterans, and the program boasts a 90% job placement rate within the defense industrial base. New cohorts begin every eight weeks, offering a fast track to meaningful careers across five trades.

The new National Training Center, a state-of-the-art, 100,000-square-foot facility on the Institute for Advanced Learning and Research (IALR) campus, opened its doors on January 13. On that day, the center welcomed its first cohort of students, marking the beginning of an expanded operation that will train 1,000 students annually, creating a pipeline of skilled workers critical for building and maintaining the nation’s submarines and warships.

“This facility helps address our immediate workforce needs,” said Frederick “Jay” Stefany, the Direct Reporting Program Manager for the Maritime Industrial Base (MIB) Program. “It advances our efforts to restore our industrial base and ensure our industry partners have the skilled workforce they need to build and maintain the Navy’s fleet.”

ATDM’s graduates are essential in addressing the maritime industry’s expanding workforce needs. The Navy’s shipbuilding plans include the construction of Columbia-class and Virginia-class submarines, along with more than 10 different classes of surface ships, including aircraft carriers, destroyers, frigates, amphibious warships, and support vessels. This unprecedented scale of shipbuilding requires a comprehensive strategy to rebuild America’s manufacturing capabilities. The establishment of the National Training Center marks a significant milestone in this endeavor.

The MIB Program leads the Navy’s workforce development initiatives while advancing shipbuilding and repair capabilities through industrial base development, supply chain resilience, and advanced manufacturing technologies. With the U.S. manufacturing base having shrunk to a third of its size from 30 years ago, the program must overcome major challenges. One of these pressing challenges involves recruiting and training 140,000 new workers over the next decade for submarine production and sustainment, with an additional 110,000 workers needed for surface vessel construction and maintenance.

“The decline in American manufacturing has created a critical skills gap,” said Erica Logan, Workforce Director for the MIB Program. “But we’re not just filling jobs—we’re rebuilding America’s maritime manufacturing capability and offering meaningful careers for the next generation of workers. Every graduate represents another step toward restoring our nation’s industrial strength.”

This workforce development initiative is vital for both new construction and fleet maintenance, underscoring the strategic importance of programs like ATDM in maintaining America’s naval readiness. This national revitalization effort takes shape through individual success stories and community partnerships.

The IALR campus, which hosts the National Training Center, also houses another key MIB Program initiative: the Navy’s Additive Manufacturing Center of Excellence. This co-location creates a hub for maritime manufacturing innovation.

Natasha Barnes, part of the inaugural class that began training January 13 in the new facility, represents a growing wave of skilled workers entering the defense manufacturing workforce.

“ATDM has done an excellent job adapting during the transition into the new facility,” said Barnes, a CNC student. “It’s been an uplifting experience to learn in such a clean and well-maintained environment. I am very excited to see what the future holds for the program.”

For Telly Tucker, president of the Institute for Advanced Learning and Research (IALR), the program’s impact goes beyond the classroom.

“This facility is about more than training—it’s about revitalizing southern Virginia,” Tucker said. “It’s creating jobs, fostering economic growth, and building a pipeline of skilled workers who will strengthen our nation’s security.”

To deliver on this promise of regional revitalization and support to national security, the National Training Center provides intensive, hands-on preparation.

ATDM’s intensive, 16-week accelerated training program provides students with 600 hours of hands-on experience in one of five trades critical to maritime manufacturing: welding, CNC machining, additive manufacturing, quality assurance, and non-destructive testing. Training runs on three shifts, mirroring the 24/7 operations of the defense industry.

“This program isn’t theoretical—it’s practical,” said Christa Reed, ATDM’s Interim Vice-President. “When our students graduate, they’re not just trained—they’re ready to hit the ground running.”

The curriculum, developed in collaboration with industry leaders, ensures students are equipped with the skills and certifications needed to meet the Navy’s rigorous standards. By simulating real-world manufacturing environments, the program prepares graduates to succeed in high-demand roles. This focused training approach directly enhances America’s maritime security.

The opening of the National Training Center represents a milestone in the Navy’s efforts to address workforce challenges and bolster the maritime industrial base. For Stefany, it’s a reminder of how these efforts impact national security.

“Every ship we build, every submarine we launch, is a promise to the American people,” Stefany said. “That promise begins here, with the people we train.”

As the Navy ramps up its fleet expansion, programs like ATDM and the new National Training Center are creating a ripple effect—transforming communities, empowering individuals, and ensuring America’s maritime superiority. The center highlights innovation, collaboration, and resilience, its impact extending beyond Danville to strengthen America’s maritime future.

The Accelerated Training in Defense Manufacturing (ATDM) program celebrated the accomplishments of its 14th cohort with a graduation ceremony at the Institute for Advanced Learning and Research (IALR) on Friday, Dec. 13. The event recognized 71 graduates who completed four months of intensive manufacturing training housed on the IALR campus in Welding, CNC Machining and Nondestructive Testing.

71 students graduated as part of the 14th ATDM cohort.

The ceremony featured a keynote address by Capt. Matthew A. Hawkins, Director of the Submarine Force Reserve Component, and remarks from two student speakers, Jack McNeel and Trevor Saunders.

The ATDM program is designed to prepare adult learners for critical roles and meaningful careers in the maritime industrial base (MIB), the system of companies that produce parts for the production and maintenance of ships and submarines. Accepted participants in the ATDM program receive scholarships for tuition and housing. The training itself is informed by industry input and aligns with the workforce needs of companies producing equipment for the MIB. The graduates completed 600 hours of hands-on instruction and earned multiple industry-recognized credentials. Many students secure employment offers prior to graduation.

“ATDM gave these graduates the opportunity to develop essential, tangible skills,” said Christa Reed, Interim Vice President of ATDM. “The abilities they gained are directly applicable to current industry needs and will continue to serve them well as they move forward. I want to congratulate the entire ATDM team for a job well done.”

Students from across the nation, representing varied backgrounds, participate in the ATDM program. Some have experience in other industries, some are new to manufacturing and others are transitioning from military service. Beginning in 2025, when the Navy’s National Training Center opens, 800-1,000 students are projected to complete the program annually.

About ATDM

Accelerated Training in Defense Manufacturing was developed as a public-private consortium between the Department of Defense, IALR, Danville Community College (DCC), Phillips Corporation and The SPECTRUM Group in consultation with the defense industry. IALR leads a multi-year pilot project to test and evaluate ATDM as a training platform for regional training centers supporting the defense industrial base. The pilot project is funded through the National Imperative for Industrial Skills initiative launched in 2020 by the Industrial Base Analysis and Sustainment Program Office (IBAS) in the Office of the Undersecretary of Defense for Acquisition and Sustainment.

About the Institute for Advanced Learning and Research

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s major footprint focuses within Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg along with the cities of Martinsville and Danville.

The U.S. Navy’s Additive Manufacturing Center of Excellence (AM CoE), a linchpin in maritime technological advancement, is located inside the Center for Manufacturing Advancement on the IALR campus. This episode highlights the AM CoE as a collaborative hub of strategic importance in meeting the U.S. Navy’s ambitious submarine production goals. This project is driving manufacturing innovation forward.

IALR Executive Vice President of Manufacturing Advancement Jason Wells is joined by Advanced Manufacturing Director Jesse Geisbert and Additive Manufacturing Program Manager Aaron Wiest, both from the Maritime Industrial Base (MIB). They discuss the impact of the Navy’s AM CoE and the success stories where the project has prototyped and delivered mission-critical parts for ships and submarines much quicker than traditional methods, such as castings and forgings, and supply chains could have. This informative discussion includes:

Growing up, Mychal Carter lived in Section 8 housing and frequently visited food pantries with his mom.

After spending 10 years in the hospitality industry and then working as a deckhand on bulk carriers in the Great Lakes, Carter recently completed the welding track of the Accelerated Training in Defense Manufacturing (ATDM) program. During his time enrolled in ATDM, Carter volunteered his time at food pantries and other service opportunities, giving back to Danville and Southern Virginia.

Mychal Carter was the student speaker at the ATDM completion ceremony on Oct. 25.

“It’s coming full circle. Being on the other side of it and being able to help people has been incredible,” he said.

A four-month program based at and instructed by the Institute for Advanced Learning and Research (IALR), the ATDM program prepares adult learners for manufacturing careers that support the defense industrial base and maritime industrial base – the system of companies that produce parts and equipment for the U.S. military.

The ATDM staff is working hard to provide quality instruction and a variety of career and support services and to give students opportunities to contribute to the success of Southern Virginia.

“We’re trying to meet the needs of our students and meet the needs of the people in Danville and Southern Virginia at the same time. Many of these organizations help our students, so we are contributing to them as well.” – Sherlina Thomas, Ph.D., Assistant Director, ATDM Community Engagement and Support, IALR

ATDM is a prototype training platform for rapidly training skilled workers for the defense industry. It is a public-private consortium, in consultation with the defense industry, between the Department of Defense, IALR, Danville Community College (DCC), Phillips Corporation and The SPECTRUM Group. ATDM is one of several training programs offered by IALR’s Manufacturing Advancement division.

Thanks to federal funding from the U.S. Department of Defense and Navy, ATDM students receive tuition scholarships and access wrap-around support services such as housing, career preparation and transportation at no cost.

These services are designed to make the ATDM program more accessible to students from all different career, socioeconomic and geographic backgrounds. To date, students have come from 46 states and range in age from 18 to 50.

The ATDM team at IALR also helps connect students with needs to relevant resources and organizations for food insecurity, medical care and more.

“Many students come to the ATDM program looking for a new career and a completely fresh start, and many leave everything behind,” Thomas said. “Our goal is to support those students who are facing food insecurity and need additional resources.”

Many of those same students – as well as those who aren’t utilizing the services from area nonprofits – are now contributing to the success of those programs.

“I was expecting to come here and focus on welding,” Carter said. “We’re provided housing and training at no cost, so I just thought it was the right thing to do to give back to the community providing for us.”

The ATDM team places significant emphasis on community outreach and engagement. The goal is to connect the students with the community and its resources and encourage them to invest back into the community.

Students have spent time helping Habitat for Humanity with the construction of homes, supporting food pantries and community distribution/outreach efforts, and cleaning up community spaces. In November, they are scheduled to participate in a suicide prevention walk.

Students have volunteered with:

In many cases, Thomas can gather 20-30 students to help with a given activity, allowing them to make a significant impact in a relatively short time.

God’s Final Call and Warning—a local nonprofit that provides resources to those in poverty and holds monthly giveaway events—is one of the organizations that ATDM students have supported the most. While ATDM students utilize the food and clothes provided, they also volunteer during the giveaway events for the community.

“For the last several months, we would not have been able to do what we did without these students. They really help us get a lot done and serve a lot of people. When you have massive numbers of people, you need lots of people to organize the process. Otherwise, things become chaotic.” – Ralph Rhyne, God’s Final Call and Warning

During these events, the ATDM students manage different stations and ensure that everyone coming through receives an appropriate amount of supplies.

“The ATDM students have been an immeasurable help,” Rhyne said. “They help us organize and serve the crowd. We depend on them.”

Allowing students to contribute and volunteer does not just benefit the organizations and people they serve. These experiences also help the students themselves.

“If you feel like you have stake and ownership, if you’re giving back and investing, you will be more successful and have a better chance of completion,” Thomas said.

Recent welding graduate Hanna Williamson participated in almost all the volunteer activities offered during her four-month experience.

“It’s a nice feeling. I would be out in the community and see students from the ATDM program, but then I would see people from the community that I volunteered with and people who came to get services.” – Hanna Williamson, ATDM Welding Graduate

Carter plans to take his volunteer experience to his new career and home.

“It kept me humble throughout this process and made me want to volunteer more down the road wherever I end up,” he said.

Community organizations and nonprofits interested in supporting ATDM students or having ATDM students support them should contact Sherlina Thomas.

“I love that IALR moves at the speed of business. Things happen here fast.” – Virginia Governor Glenn Youngkin

The Institute for Advanced Learning and Research (IALR) is proud to announce the release of its Annual Report for Fiscal Year 2024, covering the period from July 1, 2023, to June 30, 2024. This year was defined by strategic collaboration that drove collective innovation, growth and success across Southern Virginia.

“At IALR, our success is not achieved in isolation but through meaningful collaborations across sectors.” – Telly Tucker, IALR President

Below are some of our valued partners:

Below are some of our valued partners:

Here are the key highlights that showcase how our work and partnerships are making a difference.

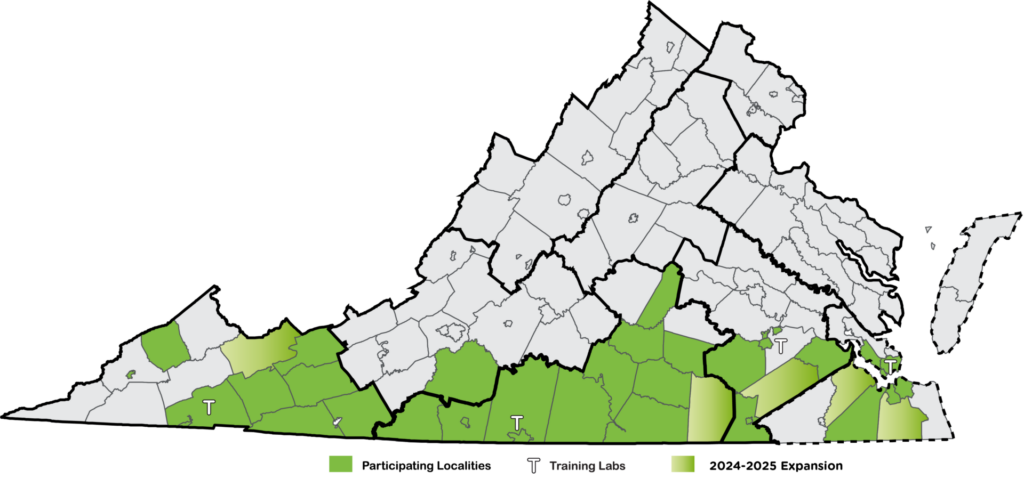

One of the most significant achievements last year was the expansion of the Great Opportunities in Technology and Engineering Careers (GO TEC®) program. Through a network of partnerships involving public schools, higher education and industry leaders, over 6,000 Virginia students received hands-on career introductions. GO TEC continues to inspire students and build dependable talent pipelines for strategic sectors, ensuring our youth are prepared for tomorrow’s careers.

GO TEC curriculum will be taught in 52 middle schools across the Commonwealth of Virginia during the 2024-2025 academic year.

“GO TEC is awesome because it allows students to explore careers and equipment that they would not have access to otherwise.” – Amy Maloskey, GO TEC Teacher, Rural Retreat Middle School, Wythe County

Learn More in the 2024 Annual Report

The Expanding Talent through Registered Apprenticeship (ExTRA) program saw remarkable progress, supporting the creation of apprenticeship programs across nontraditional sectors. This year marked the launch of Virginia’s first Registered Apprenticeship programs for EMTs and paramedics. The program’s success demonstrates the importance of partnerships between employers, training providers and community organizations to meet our region’s workforce needs.

In partnership with IALR, the Danville Life Saving Crew – the primary Emergency Medical Services provider for the City of Danville – signed 13 individuals as Virginia’s first Emergency Medical Technician (EMT) registered apprentices during an October ceremony.

ExTRA Impact in Numbers:

IALR was also selected to lead the Virginia Talent + Opportunity Partnership (V-TOP) Region 3 Regional Work-Based Learning Collaborative. This initiative develops opportunities for employers and students to connect through work-based learning – and prepares both students and employers for those opportunities.

See Our Collaborative Work in the 2024 Annual Report

The Accelerated Training in Defense Manufacturing (ATDM) program continues to grow in partnership with the U.S. Navy, rapidly training talent for the defense industry. Approximately 328 students graduated across four cohorts in the 2024 fiscal year.

By 2025, the ATDM program aims to graduate 800 to 1,000 students annually, solidifying the region’s status as a hub for advanced manufacturing training.

“ATDM’s ability to refine and scale to meet our urgent workforce needs is crucial to building America’s submarine fleet. Together, we’re not just training workers, we’re securing America’s maritime future.” – Erica Logan, Maritime Industrial Base Director for Workforce Development

Additionally, the Integrated Machining Technology (IMT) program, a legacy initiative of IALR and Danville Community College (DCC), remains a cornerstone of our manufacturing training efforts.

See Our Successful Partnerships in the 2024 Annual Report

In collaboration with local governments, the Virginia Economic Development Partnership and the Southern Virginia Regional Alliance, our Economic Development team contributed to significant economic progress in the region. Over $212 million in new capital investments and the creation of 253 new jobs were key outcomes this year, providing a solid foundation for future economic growth. IALR also hosted essential events such as the 2023 Southern Virginia Regional Housing Summit and the 2024 Workforce Solutions Summit to support long-term development.

“The efforts of the SVRA and the many regional partners should be considered best practices for other communities and regions to follow.” – Edward D. Ober, Grant Management Associates

Discover More Impact in the Annual Report

Through a series of strategic initiatives, IALR is advancing additive manufacturing (AM) technology, equipping end users with the skills needed to leverage these capabilities, and driving the growth of additive manufacturing across Southern Virginia. Much of this work is in partnership with the U.S. Navy through the Naval Sea Systems Command (NAVSEA) and Naval Air Systems Command (NAVAIR).

|

|

Initiatives in Additive Manufacturing:

By combining training, technology development and partnerships, IALR is making significant strides in establishing Southern Virginia as a leading hub for additive manufacturing.

See More in the 2024 Annual Report

As Virginia’s hub for high-performance manufacturing optimization and advancement, the Center for Manufacturing Advancement (CMA) equips manufacturers to be globally competitive. The CMA at IALR is the destination for innovative manufacturers ready to optimize their operations and scale. With state-of-the-art facilities and technology—including a CNC Machining Innovation Lab, Industry 4.0 Integration Lab and Precision Metrology Lab – the CMA is helping clients and partners optimize operations and scale.

See the Complete Annual Report

IALR’s Applied Research division offers various services in controlled environment agriculture (CEA), analytical chemistry, biotechnology and life sciences. These include conducting contract research, providing chemistry testing services and supporting biotechnology development—all aimed at meeting the needs of industry partners and advancing the scientific community.

“IALR has provided Canon the environment and expertise to grow plants under various stress conditions in an effort to understand how these stresses present themselves in the plants. IALR is unique in this capability.” – Benjamin Welch, Principal Engineer, Canon

Equipped with state-of-the-art and flexible facilities, the IALR Conference Center experienced impressive growth, hosting over 30,000 guests last year. This increase is a testament to its role as a vital space for collaboration across business, education and community sectors.

“The IALR Conference Center offers a turnkey experience and state-of-the-art technology to deliver a high level of professionalism and engagement. Their staff are accommodating, easy to work with and attentive to the details.” – Stephanie Mann, Center for Early Success

IALR’s Advanced Learning team collaborates with numerous partners to increase STEM capacity, promote lifelong learning, and provide regional service-learning opportunities. These initiatives contribute to a better Southern Virginia where all can thrive.

“IALR is an exceptional and long-standing partner to Serve Virginia. The services they provide through their AmeriCorps program, Dan River Year, are impactful and make a real difference in the communities they serve.” – Samantha Lukasiewicz, AmeriCorps Manager

FY 2024 was notable for the growth of IALR’s campus and support services. The number of team members nearly doubled to meet increasing demands, reflecting the strength of the partnerships and the impact IALR has cultivated in Southern Virginia. With new facilities like the Navy’s National Training Center opening in early 2025, IALR is poised to continue driving regional growth and innovation.

“The near doubling of our team and the expansion of our campus highlight the incredible momentum we’ve gained through strategic internal and external collaboration. With new facilities like the Navy’s National Training Center on the horizon, IALR’s IT, Facilities and other support services ensure seamless operations for efficient growth and regional success for years to come.” – John H. Hughes, IV, Ed.D, Executive Vice President, Operations, IALR

A political subdivision of the Commonwealth of Virginia, IALR is governed by a Board of Trustees.

“As we review another year of strong financial performance, it’s clear that our partnerships and strategic initiatives deliver real value to the region. Our board remains dedicated to guiding IALR toward continued success, ensuring that every dollar invested helps drive meaningful economic transformation in Southern Virginia.” – Donald W. Merricks, Chairman, IALR Board of Trustees

Accelerated Training in Defense Manufacturing (ATDM) celebrated the achievements of 93 students who graduated as part of the program’s 13th cohort during a ceremony on October 25 at the Institute for Advanced Learning and Research (IALR). This is the largest graduating cohort to date. This program prepares adult learners for manufacturing careers that directly support the defense industrial base (DIB) and submarine industrial base (SIB).

Captain Jason Deichler, Commodore of Commander, Submarine Squadron Two, served as the keynote speaker for the completion ceremony.

“These graduates will be ready to contribute to their employers on day one,” he said.

The ATDM program is an intensive, 16-week training initiative designed to equip adult learners with the skills needed to work in the SIB and DIB. This system of companies produces crucial parts and equipment for the U.S. military.

ATDM aims to expand the pool of skilled workers in five tracks—welding, CNC machining, additive manufacturing, non-destructive testing, and quality control inspection (metrology)—needed to develop submarines and other military equipment. The program includes 600 hours of hands-on training and produces graduates with industry-recognized credentials.

Welding student Mychal Carter of Massachusetts, the student speaker for the ceremony, shared the story of how he found the ATDM program on social media and is now graduating with 10 welding certificates and a career lined up.

Mychal Carter, Student Speaker at the completion ceremony for the 13th cohort of the ATDM program.

“I have no fear of the unknown, but I have a thirst for knowledge, and that’s what ATDM gave me,” he said.

This cohort included students from CNC machining, additive manufacturing, welding and non-destructive testing. Training was conducted across multiple shifts, accommodating a variety of schedules to make this vital training accessible to adult learners.

This cohort brings the total number of ATDM graduates to 708 since the program launched in 2021.

Looking ahead, approximately 800-1,000 students are projected to graduate annually from the ATDM program starting in 2025. The Navy’s National Training Center, located on IALR’s campus, is currently under construction and is slated for completion in 2025. Once operational, each of the five training tracks will be available across three shifts, further boosting the number of skilled workers available for critical defense industry needs.

About IALR

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation with applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s major footprint focuses within Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg, along with the cities of Martinsville and Danville. IALR houses and leads the Accelerated Training in Defense Manufacturing program with the support of various partners.

About ATDM

Accelerated Training in Defense Manufacturing is a prototype training platform for rapidly training skilled workers in key trades such as CNC machining and welding for employment in the defense industry. ATDM was developed as a public-private consortium between the Department of Defense, IALR, Danville Community College (DCC), Phillips Corporation and The SPECTRUM Group, in consultation with the defense industry. IALR is leading a multi-year pilot project to test and evaluate ATDM as a training platform for regional training centers supporting the defense industrial base. The pilot project is funded through the National Imperative for Industrial Skills initiative launched in 2020 by the Industrial Base Analysis and Sustainment Program Office (IBAS) in the Office of the Undersecretary of Defense for Acquisition and Sustainment.

The October 2024 edition of IALR at a Glance is jam-packed with exciting news and updates! Learn more about…

The Accelerated Training in Defense Manufacturing (ATDM) program provides comprehensive and unique support and career services from the day students arrive. This level of support makes the program more successful and accessible.

This episode features three ATDM staff to highlight those services and how they enhance student experiences and outcomes: Kevin Gatewood, Assistant Director, ATDM Student Services; Karen Hardy, Assistant Director, ATDM Career Services and Dr. Debra Holley, Director, ATDM Project Development.

The September 2024 edition of IALR at a Glance is jam-packed with exciting news and updates! Learn more about…

The Institute for Advanced Learning and Research (IALR) is a hub for innovative and effective workforce training.

This talent development focus ranges from a national accelerated training program housed on the IALR campus in partnership with the U.S. Navy to a regional program that helps businesses establish and maintain effective apprenticeship programs.

Now those two programs are collaborating.

The Accelerated Training in Defense Manufacturing (ATDM) program has been approved by the Virginia Department of Workforce Development and Advancement (Virginia Works), Division of Registered Apprenticeship, as a private provider of related technical instruction (RTI) for employers in Virginia in five program areas: welding, CNC machining, quality control inspection (metrology), non-destructive testing and additive manufacturing.

“Having ATDM registered as a training provider for apprenticeship programs gives employers more incentive to send conditional hires, upskill incumbent workers and recruit new employees through our program. It is attractive to them to engage with us if we can transfer those hours into their apprenticeship program.” – Karen Hardy, Assistant Director, ATDM Career Services, IALR

This means companies that support the defense industrial base or submarine industrial base in Virginia – as well as Maine and Massachusetts, where ATDM has also been approved as an apprenticeship instruction provider – can hire apprentices and use the ATDM program as their classroom instruction (or RTI). Conversely, they can hire students who complete the program, bringing them into an existing apprenticeship program and crediting the ATDM course as their RTI.

The Expanding Talent through Registered Apprenticeship (ExTRA) program at IALR supports the creation and implementation of apprenticeship programs in Southern Virginia across all sectors, with an initial focus on construction, healthcare, early childhood education, manufacturing and information technology.

Through the ExTRA program, IALR has helped dozens of Southern Virginia businesses establish apprenticeship programs across different industries, including manufacturing.

“These apprenticeship programs are customizable to meet employer needs and align with industry standards. An effective program helps recruit, train and retain a highly skilled workforce for a business and improves the employee experience.” – Natori Neal, Apprenticeship Coordinator II, IALR

Every apprenticeship combines two primary elements: paid on-the-job training and related technical instruction (RTI). These programs’ timelines and lengths vary by industry and company preferences.

Many employers structure the program so that classroom time and on-the-job training are largely happening simultaneously. Another option is to have the employees complete most classroom instruction at the beginning. This front-loading of classroom instruction is how the Danville Life Saving Crew – which launched the first registered EMT apprenticeship program in Virginia with support from IALR – arranged its program.

And this front-loading of instructional time is how ATDM can support manufacturing employers with apprenticeship programs in Virginia. If potential students are within driving distance, ATDM could also support manufacturing employers using the traditional RTI model. The employer could maintain classroom time and on-the-job training simultaneously – with students working first shift and attending class during second or third shift.

The largest workforce initiative on the IALR campus is Accelerated Training in Defense Manufacturing (ATDM). This training program prepares workers for careers that will contribute to the development of ships and submarines for the U.S. Navy. Approximately 10,000 new workers must enter the defense industrial and submarine industrial bases every year for the next 10 years to meet submarine construction and maintenance needs.

Students can attend independently and, with help from a job placement team, seek a career upon graduation. Companies can also send conditional hires, using the program as an onboarding training opportunity. The ATDM program, which is recognized and approved to provide training for apprenticeship programs in Virginia, is helpful for students following either of these tracks.

“ATDM provides entry-level, foundational skills. Graduates will still need a training pathway when they are hired. For employers with an existing apprenticeship program, this is a great way to get qualified workers started and into the company.” – Karen Hardy, Assistant Director, ATDM Career Services, IALR

ATDM staff are working with employers to expand apprenticeship training opportunities on a state-by-state basis. The goal is for ATDM to eventually be approved as an education provider for apprenticeship programs on the national level.

“ATDM and Registered Apprenticeship are a perfect match. We look forward to supporting employers with apprenticeship programs in Virginia, and we are optimistic that in the future we will be able to provide instruction for relevant apprenticeship programs all around the country.” – Dr. Debra Holley, Director, ATDM Project Development, IALR

Companies interested in sending conditional hires through ATDM or hiring program graduates should contact Karen Hardy, Assistant Director, ATDM Career Services.

Southern Virginia employers who want to learn more about the benefits of Registered Apprenticeship should contact Natori Neal, the apprenticeship coordinator at IALR.

Accelerated Training in Defense Manufacturing (ATDM) celebrated the achievements of 56 students who graduated as part of the program’s 12th cohort during a ceremony on Aug. 7 at the Institute for Advanced Learning and Research (IALR). This program prepares adult learners for manufacturing careers.

The keynote speech during the event was all about the impact these graduates will make.

“It doesn’t matter where you’re going to work. You are contributing to national security. You are helping the United States of America exercise power projection and diplomacy from whatever shop floor or office you’re going to work in.” – Command Master Chief Jeff Hiscocks, Program Executive Office, Team Submarines

A 16-week, hands-on program, ATDM prepares adult learners with the skills needed to work in the submarine and defense industrial base – the system of companies that produce parts and equipment for the U.S. military. ATDM includes 600 hours of instruction and produces skilled talent with industry-recognized credentials. This program expands the pool of skilled workers in five tracks – welding, CNC machining, additive manufacturing, non-destructive testing and quality control inspection (metrology) – needed to develop submarines and other military equipment.

This cohort included students from welding, CNC machining and metrology across multiple shifts.

During a speech during the graduation ceremony, metrology student Qian Yi (Cyndi) Rong shared her experiences working full-time while completing the ATDM program. After experience as a machinist and working in leadership roles in the hospitality industry, Rong now plans to work with BWX Technologies in Lynchburg.

“The comprehensive curriculum and hands-on training have prepared us to tackle real-world problems. But beyond the technical knowledge and practical skills, this program has also taught us the importance of perseverance, collaboration and adaptability.” – Qian Yi (Cyndi) Rong, Metrology Student

This cohort brings the total number of ATDM graduates to 615 since the program launched in 2021.

Approximately 800-1,000 students will graduate from the ATDM program annually starting in 2025. The Navy’s National Training Center, housed on IALR’s campus, is under construction and slated for completion in 2025. When the training center is completed, each of the five tracks will be offered across three shifts.

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation through applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s primary footprint focuses within Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg, along with the cities of Martinsville and Danville. IALR houses and leads the Accelerated Training in Defense Manufacturing program with the support of various partners.

IALR Drives Economic Transformation

Accelerated Training in Defense Manufacturing is a prototype training platform for rapidly training skilled workers in key trades such as CNC machining and welding for employment in the defense industry. ATDM was developed as a public-private consortium between the DoD, IALR, Danville Community College (DCC), Phillips Corporation and The SPECTRUM Group in consultation with the defense industry. IALR is leading a multi-year pilot project to test and evaluate ATDM as a training platform for regional training centers supporting the defense industrial base. The pilot project is funded through the National Imperative for Industrial Skills initiative launched in 2020 by the Industrial Base Analysis and Sustainment Program Office (IBAS) in the office of the Undersecretary of Defense for Acquisition and Sustainment.

The August 2024 edition of IALR at a Glance is jam-packed with exciting news and updates! Learn more about…

The July 2024 edition of IALR at a Glance is jam-packed with exciting news and updates! Learn more about…

IALR President Telly Tucker returns for the one-year anniversary episode of Inside IALR to discuss the biggest successes and lessons learned from his two years with the organization. As IALR continues to grow, Telly explains the level of growth and impact not only regionally but nationally and internationally in areas such as GO TEC, ATDM and Applied Research. Telly also highlights his vision for IALR two years from now.

Accelerated Training in Defense Manufacturing (ATDM) celebrated the achievements of 87 students who graduated as part of the program’s 11th cohort during a ceremony on June 11 at the Institute for Advanced Learning and Research (IALR). To date, this was the largest cohort of graduates in the program, which prepares adult learners for manufacturing careers.

“ATDM is a skilled-labor boot camp. This is such an important program. You all are part of the Navy as far as I’m concerned, whether you’re in uniform or not.” – Matthew Zirkle, Retired U.S. Navy Rear Admiral

A 16-week, hands-on program, ATDM prepares adult learners with the skills needed to work in the submarine and defense industrial base – the system of companies that produce parts and equipment for the U.S. military. ATDM includes 600 hours of instruction and produces skilled talent with industry-recognized credentials. This program expands the pool of skilled workers in five tracks – welding, CNC machining, additive manufacturing, non-destructive testing and quality control inspection (metrology) – needed to develop submarines and other military equipment.

This cohort included students from welding, CNC machining, non-destructive testing and additive manufacturing across multiple shifts.

Margaret Abrams, who completed the third-shift CNC Machining program and will work with Huntington Ingalls in Newport News, was the student speaker for the ceremony.

“I cannot express enough how fantastic of an opportunity ATDM is. This has been a dream come true. I’m sad to leave but thrilled to start my new job.” – Margaret Abrams, ATDM Graduate

This cohort brings the total number of ATDM graduates to 559 since the program launched in 2021.

Approximately 800-1,000 students will graduate from the ATDM program annually starting in 2025. The Navy’s National Training Center, housed on IALR’s campus, is under construction and slated for completion in 2025. When the training center is completed, each of the five tracks will be offered across three shifts.

The Institute for Advanced Learning and Research serves Virginia as a regional catalyst for economic transformation through applied research, advanced learning, manufacturing advancement, conference center services and economic development efforts. IALR’s primary footprint focuses within Southern Virginia, including the counties of Patrick, Henry, Franklin, Pittsylvania, Halifax and Mecklenburg, along with the cities of Martinsville and Danville. To learn more, click here.

Accelerated Training in Defense Manufacturing is a prototype training platform for rapidly training skilled workers in key trades such as CNC machining and welding for employment in the defense industry. ATDM was developed as a public-private consortium between the DoD, IALR, Danville Community College (DCC), Phillips Corporation and The SPECTRUM Group in consultation with the defense industry. IALR is leading a multi-year pilot project to test and evaluate ATDM as a training platform for regional training centers supporting the defense industrial base. The pilot project is funded through the National Imperative for Industrial Skills initiative launched in 2020 by the Industrial Base Analysis and Sustainment Program Office (IBAS) in the office of the Undersecretary of Defense for Acquisition and Sustainment. To learn more, click here.

This episode features Accelerated Training in Defense Manufacturing (ATDM) Industry Engagement Coordinator Justin Scarce, current ATDM Non-destructive Testing student Brandon Payne and Pegasus Steel Senior Talent Acquisition Manager Bria Major. The ATDM career fair gives employers the opportunity to meet, interview and hire ATDM students. With a recent attendance of 115 students and over 25 employers, these fairs help place skilled technicians in the following types of jobs:

Justin Scarce talks about the accelerated need for skilled labor and how skilled trades tie into the future of the American dream.

Brandon Payne discusses how he learned about ATDM, his job-seeking experience with employers at the career fair and what he’s hoping to find after graduation.

Bria Major talks about how rewarding it to both recruit students once they complete the ATDM program and also send employees for further training as an industry sponsor.

The Institute for Advanced Learning and Research (IALR) is leading the ATDM program. This is a Navy-funded workforce development and job placement program which rapidly develops skilled technicians for the manufacturing sector supporting national defense.

Supply chain gaps and delays mean that a critical part failure can cause long delays and reduce the operational readiness of our nation’s critical warfighting weapon system.

For example, a mission-critical part breaks on an aircraft carrier full of personnel after it leaves the pier and is on deployment. If that part is not spared aboard the aircraft carrier, it could take months to get that replacement part delivered to the ship.

Additive manufacturing—or industrial 3D printing—is a growing solution to expensive and potentially compromising distribution bottlenecks. It allows the military to address supply chain issues and, in many cases, allows maintenance personnel to print critically needed parts on-demand, on-site.

“Even in peacetime, there are a lot of situations where supplies and parts just aren’t available. There’s a genuine need to be able to reverse engineer or redesign parts to be able to return that aircraft and/or weapon system to an operational status.” – CAPT Alexander Peabody, senior fleet liaison officer, Naval Air Systems Command (NAVAIR) Additive Manufacturing Team

CAPT Alexander Peabody, senior fleet liaison officer, Naval Air Systems Command (NAVAIR) Additive Manufacturing Team, participates in an open house celebration of the new NASAM program housed at and instructed by IALR.

The Naval Aviation School for Additive Manufacturing (NASAM)—a six-week program that provides active-duty Navy and Marine Corps maintenance personnel with foundational skills in additive manufacturing—launched with a pilot cohort of 12 students in February 2024. This program provides instruction for the deployed additive manufacturing technologies and prepares the users to utilize and maximize those capabilities. The Institute for Advanced Learning and Research (IALR) hosts and instructs the NASAM program.

“IALR is proud to continue to provide technology-driven workforce development programs by partnering with NAVAIR to deliver a high-quality curriculum in support of their additive manufacturing capabilities. Being able to train the end users in our fast-paced technology development environment and quickly adjust the curriculum to capitalize on industry feedback is the unique value of what is happening at IALR.” – Telly Tucker, president, IALR

Featured above is the second cohort of the six-week NASAM program, which provides active-duty Navy personnel with foundational additive manufacturing skills.

Additive manufacturing, also called industrial 3D printing, is a subset of manufacturing where an object is built “from the ground up” based on a 3D model. The more traditional approach, subtractive manufacturing is the inverse, where a block is whittled down into whatever shape or design is needed. This allows for the unmatched design and manufacturing versatility needed to produce functional components at the pace and intricacy needed to remain globally competitive.

After starting as a niche technology primarily used for prototyping, additive manufacturing has emerged as a cost-effective, efficient option across industries. Advancements in materials science, software development and hardware engineering have allowed for expanding material options beyond plastics to include metals, ceramics and even biomaterials, propelling additive manufacturing into the mainstream.

“Additive manufacturing is ‘NOW,’ and it’s where we need to be.” – James Hubbard, director of training and technology, IALR Manufacturing Advancement

James Hubbard, director of training and technology for IALR’s Manufacturing Advancement division, speaks about IALR’s work in technology and workforce development in additive manufacturing at a recent open house event celebrating the launch of the NASAM program.

This growth is happening across sectors ranging from aerospace and healthcare to automotive. The Department of Defense is also investing in additive manufacturing technologies to better protect our country.

For the U.S. Navy, much of that activity is centered at the IALR campus. These initiatives align with IALR’s goals to serve as a center of excellence for workforce development, to serve as a hub for high-tech companies and to support employers so they can be globally competitive.

Through several distinct but connected initiatives in collaboration with the U.S. Navy, IALR’s Manufacturing Advancement division is helping mature additive manufacturing technology and preparing the end users to utilize those capabilities. NASAM is the newest component of that multi-pronged approach.

“We are becoming an additive manufacturing center of gravity.”

“We are becoming an additive manufacturing center of gravity. We are partnering with the U.S. Navy’s NAVSEA and NAVAIR Commands to implement and train these technologies in many ways. Through different initiatives, we are preparing sailors and Marines to use additive technologies, training the additive workforce for Navy suppliers, and helping the Navy to develop additive technologies and processes that supplier companies can utilize.” – James Hubbard, director of training and technology, IALR Manufacturing Advancement

“We are giving the fleet maintainers the proficiency to match the equipment we provide them with.”

That’s how CAPT Alexander Peabody explains the NASAM program. This fast-paced pilot program is a six-week course that provides 240 hours of hands-on instruction using different polymer 3D printing technologies.

In those six weeks, NASAM prepares learners to work with the designated equipment. Students learn about equipment operation, reverse engineering and measurement fundamentals, computer-aided design (CAD), material evaluation, Naval additive manufacturing policies, procedures and more.

“This course will give them a limited ability to maintain their own production capabilities for their units. We are creating the advanced military workforce of tomorrow.” – CAPT Alexander Peabody, senior fleet liaison, NAVAIR Additive Manufacturing Team

Students in the first cohort included:

One of the participants in this first cohort was a fabrication platoon commander with the U.S. Marine Corps based in Camp Pendleton in California. With 16 years of experience and current duties that involve overseeing welding, machining and additive work from his team, Gunnery Sgt. Mark Cureo participated to learn more about how the Navy is approaching additive technologies and processes.

U.S. Marines Gunnery Sgt. Mark Cureo (left) was one of the participants in the first cohort of the NASAM program housed at and instructed by IALR.

“This collaborative effort aims to showcase the activities of various forces and align strategies. Courses of this nature contribute to establishing a standardized approach for additive manufacturing within the Department of Defense.” – Gunnery Sgt. Mark Cureo, U.S. Marine Corps

On the other end of the spectrum, AM3 Skyler Berry is an aviation structural mechanic working aboard a U.S. Navy aircraft carrier. The carrier he supports was recently outfitted with a Tier 1 system, but Berry was the first to receive training on that specific machine.

“The instruction is great, and I’m feeling more confident than I thought I would,” Berry said.

U.S. Navy AM3 Skyler Berry was one of the participants in the first cohort of the NASAM program housed at and instructed by IALR.

The third cohort of this NAVAIR program is set to begin in late May.

NAVAIR’s NASAM program is the newest manufacturing training program housed at IALR. It’s a direct offshoot of the ATDM model: short, accelerated, fast-paced and personalized instruction. With five different tracks, ATDM prepares adult learners for needed positions across the defense and submarine industrial bases—the system of supplier companies for the military.

“All of this is falling on the success and unique training model of ATDM. One-on-one time with the equipment and one-on-one time with the instructors make training in Danville successful and unique. Those are two of the things that put us on the map.” – James Hubbard, director of technology and training, IALR Manufacturing Advancement

The idea to utilize this model for a Naval additive manufacturing school came during the 2022 ATDM Summit when CAPT Alexander Peabody and other Naval leaders heard a presentation about the ATDM curriculum and model.

“We identified early on that we need sufficient operators in the field to maximize what these machines can do. We need skilled, proficient technicians. So, we imagined a more formal school for our sailors and marines to go to get a more intense, hands-on training experience, and the accelerated model from ATDM was a perfect fit,” CAPT Peabody said.

They immediately began conversations with IALR staff on how that model could be tweaked to create a standalone course for additive manufacturing. Several active-duty personnel from NAVAIR went through the traditional additive manufacturing track of ATDM while this spinoff program was designed.

Another connection point: the program’s instructor, Daniel Hyler, is a successful completer of two separate tracks of the ATDM program. Fresh out of high school, Hyler secured one of the last spots in the first cohort for Computer Numerical Control (CNC) Machining. FasTech, an additive manufacturing company on the IALR campus, hired him out of the program and later sent him back as part of the first additive manufacturing cohort. After another eight months with FasTech, Hyler joined ATDM as a technician for the additive manufacturing class – a position he held for about a year before becoming the instructor for NASAM.

“Daniel brought an ideal skillset to the table based on his experiences as an ATDM graduate in both CNC Machining and Additive Manufacturing, time working at FasTech and his success serving as an ATDM Additive Manufacturing Technician training adult learners.” – James Hubbard, director of training and technology, IALR Manufacturing Advancement

Daniel Hyler, left, completed two separate tracks of the Accelerated Training in Defense Manufacturing (ATDM) program, and now serves as the instructor for the Naval Aviation School for Additive Manufacturing.

“My education and career are so intertwined with IALR, ATDM and ultimately the Navy. It is humbling and inspiring to know that I am now contributing to our nation’s defense by helping active-duty Navy personnel become proficient and efficient with these 3D industrial printing machines.” – Daniel Hyler, NASAM instructor, IALR

The June 2024 edition of IALR at a Glance is jam-packed with exciting news and updates! Learn more about…